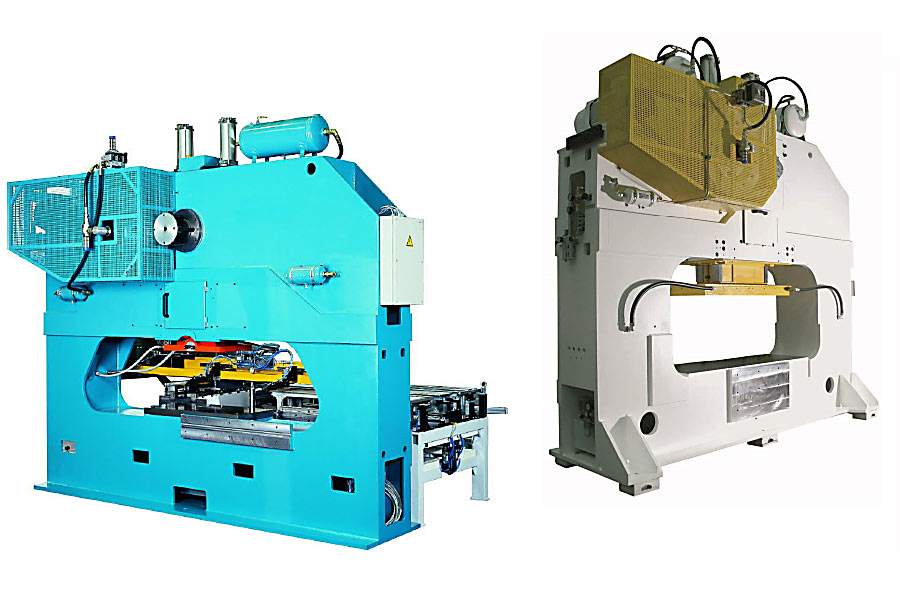

The press CM-100 was developed by a closure manufacturer with outstanding mechanical engineering experience and has proven itself many times in the production of metal closures. | Read more

Hydraulic Balers for scrap generated in 2-piece can making are an integral part of complete removal systems from Container Machinery. | Read more

When making cans and ends, you will produce lots of scrap. When your production requires speeds of 3,600 cpm and ends up to 5000 epm, you will drown in scrap unless you do something about it. We put together complete scrap removal systems, using well known suction / conveying systems | Read more

HEILBRONN started it many years ago and O-frame presses are the industry standard today. Single and double row tool sets in leader pin designs, strokes up to 250 / min allows for high production speeds for cups and shells. | Read more

The lock-seamed body needs a bottom, needs to curl the top. Both is done in the first of its kind bottom inside seamer for fancy cans, when an outside double seam will not do. The first line is still being de-bugged. Call if you want an up-date. It will be | Read more

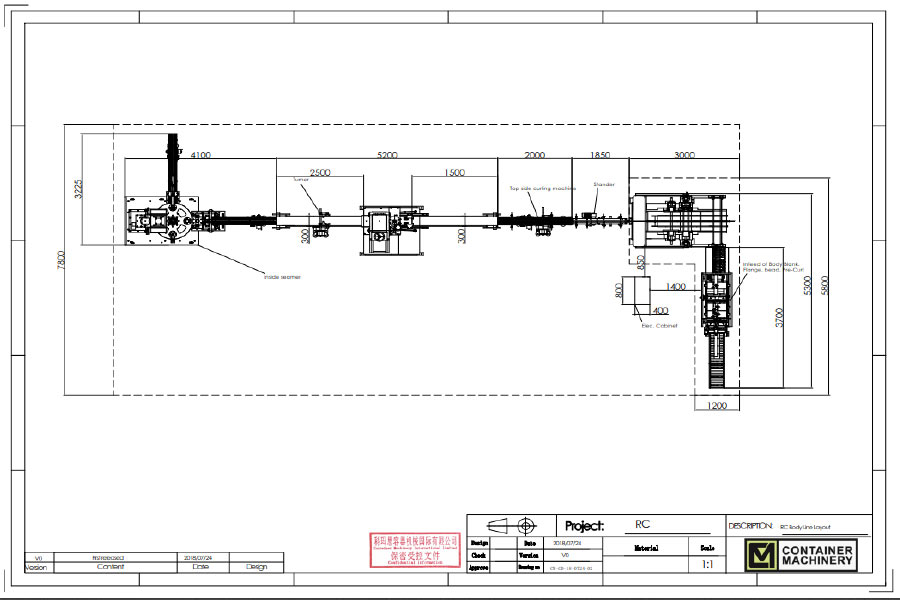

Fancy cans, odd shaped ends, small pocket cans for mints – they all need the lock-seam body makers. We can supply them for very large cans (waste baskets) to miniature cans for mints with hinged lids, from 20 cpm for the largest cans, 200cpm for the smallest ones. | Read more

We take over after the compound lining with conveyors, room for inspection stations for compound, curls, rivets, any desired parts of the ends at speeds up to 1500 epm, counting, bagging, palletising, strapping, wrapping. You just need to sell them and take them to the warehouse or the customer. | Read more