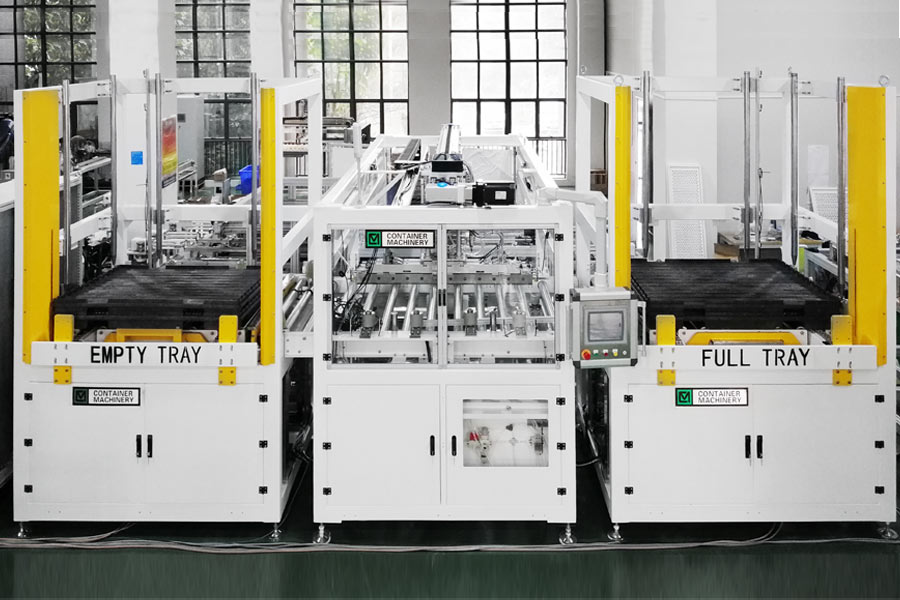

Beverage End Balancer

The efficiency of your end making line is measured by converted ends coming from the conversion press. But what happens, if your liner has to be cleaned, the shell press has to change coils, the tooling needs adjustments? Don’t worry, our A and B balancer stacks trays full of ends in case the liner stops – and if the conversion press should ever stop, you fill the lined ends into trays and take them to the warehouse, until you can use them. Any ‘ifs’ can be handled, without needing people and without a robot. Robots are cool and we use them, when we need to, but if a Pick & Place can handle it, that much the better! Take a look at the dual gripper transfers, managing 2 – 4 in and three to 4 lanes out, or any combination, up to a total speed of 3600 epm line production.

The next generation lines want to go up to 10,500 epm and our designs are ready to handle that. Maybe we have to use robots this time. We will tell you in 2022.

Type: CM-B500

- Ends type: 200,202,206

- Number of Infeed channels: 2 or 4

- Number of Out channels: 2 or 4

- Single channel speed: Max.2000 pcs/min

- Storage number: 160000 pcs

- Control system: Siemens/Allen-Bradley

- Air connection: 12mm

- Air pressure: 0.6Mpa

- Power connection: 380V 50Hz

- Power rating: 12KW

- Mechanical size: L*W*H=7m*4.5m*3.1m

- Nett weight approx.: 4200Kg

- Height per stack: 1450mm

- Stick length: 1330mm

- Sticks per tray: 12

- ends per stick: 770±10 pcs(Based on 202)

- ends per stack: 160000 pcs

Please note that the energy consumption submitted is for reference only.Device energy consumption depends on the actual system configuration for your specific requirements.