AL and FE Scrap Removal

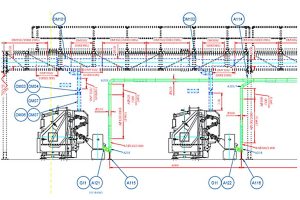

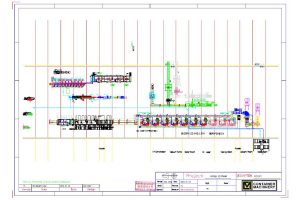

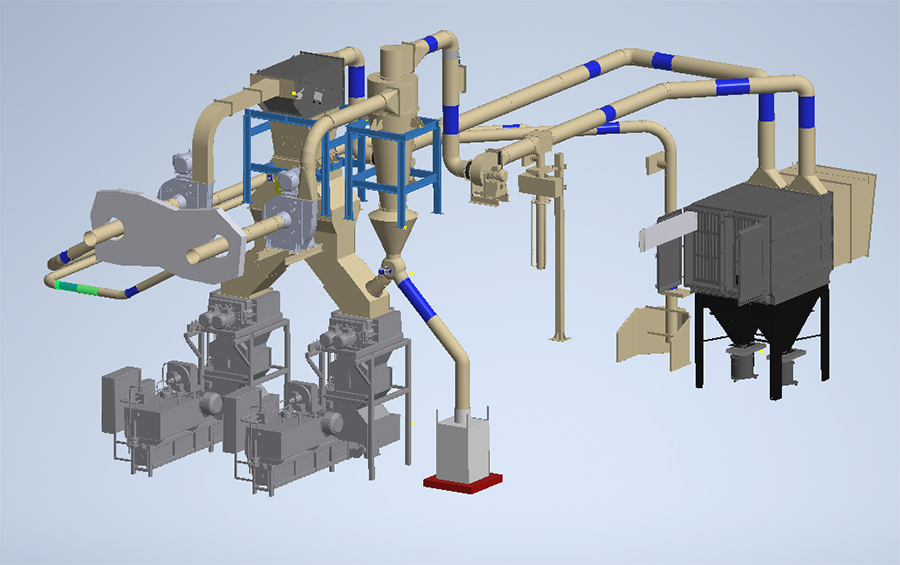

When making cans and ends, you will produce lots of scrap. When your production requires speeds of 3,600 cpm and ends up to 5000 epm, you will drown in scrap unless you do something about it. We put together complete scrap removal systems, using well known suction / conveying systems to pick up the scrap at the point of scrap generation (cupper, trimmer, decorator) and take it to the scrap room. There the separated scrap (bright and printed) is weighed and a pre-determined amount is dropped into the baler. The double acting hydraulic cylinders produce consistent bales with high density, allowing pick up by manually operated cranes or fully automatic robotic handling. This is the end of the messy and dangerous scrap room.