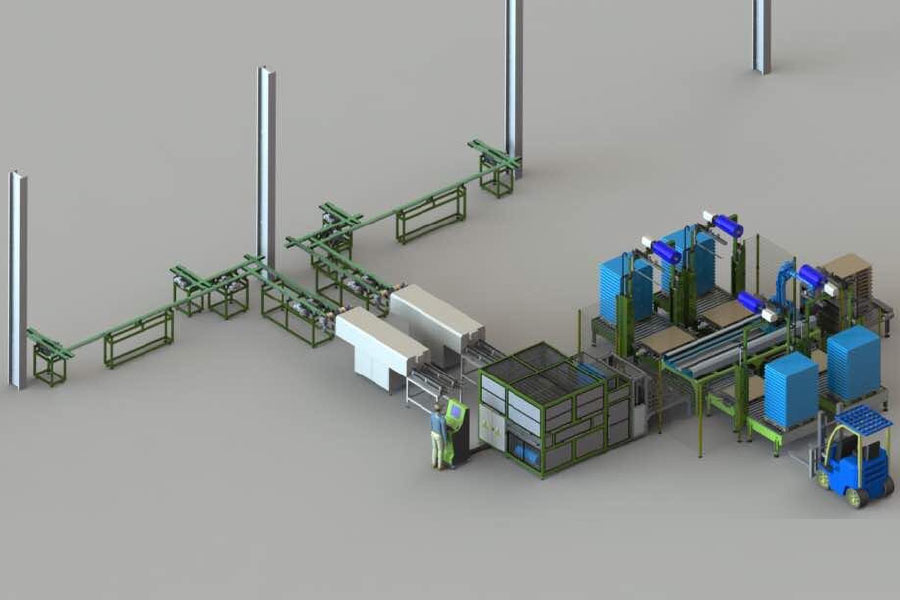

This video shows the fully automatic end delivery system for can ends in a beverage filling line. It includes a robotic de-palletiser, automatic un-wrapper, including suction device to remove paper scraps and dust, reversed end rejection, two or four roll pusher for a single or dual lane out-feed. Not shown | Read more

The press CM-100 was developed by a closure manufacturer with outstanding mechanical engineering experience and has proven itself many times in the production of metal closures. | Read more

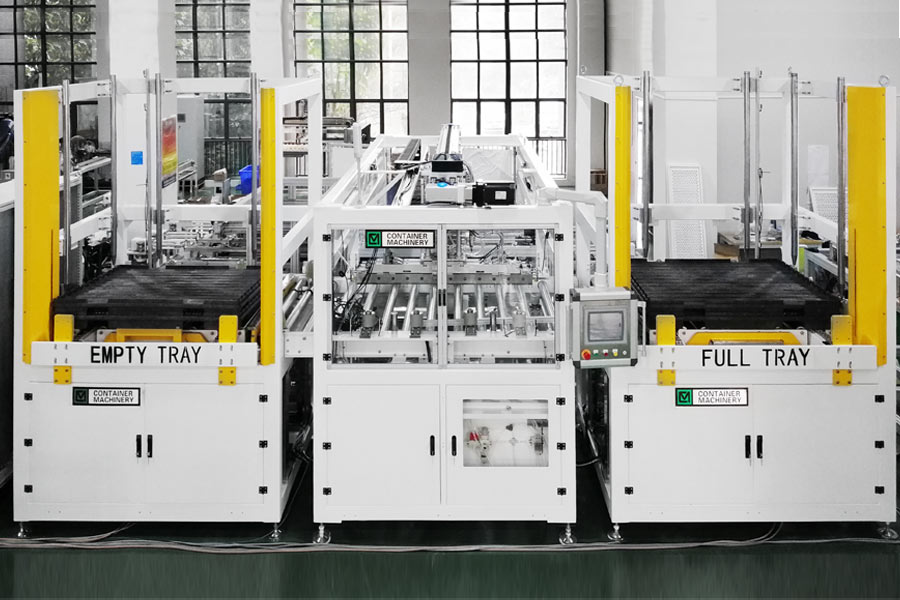

The efficiency of your end making line is measured by converted ends coming from the conversion press. But what happens, if your liner has to be cleaned, the shell press has to change coils, the tooling needs adjustments? Don’t worry, our A and B balancer stacks trays full of ends | Read more

To guarantee uninterrupted supply of can ends to highspeed can filling lines a buffer after unwrapping will keep the line running for as long as you specify. | Read more

Hydraulic Balers for scrap generated in 2-piece can making are an integral part of complete removal systems from Container Machinery. | Read more

When making cans and ends, you will produce lots of scrap. When your production requires speeds of 3,600 cpm and ends up to 5000 epm, you will drown in scrap unless you do something about it. We put together complete scrap removal systems, using well known suction / conveying systems | Read more

We integrate a European model, which is built with great care and 60 yrs experience. A capacity of 3,600 cpm makes it the fastest one available. We sell and service it in Asia. We developed a palletiser for DRD cans, for up to 1,500cpm and a no-touch pattern, avoiding scratches | Read more

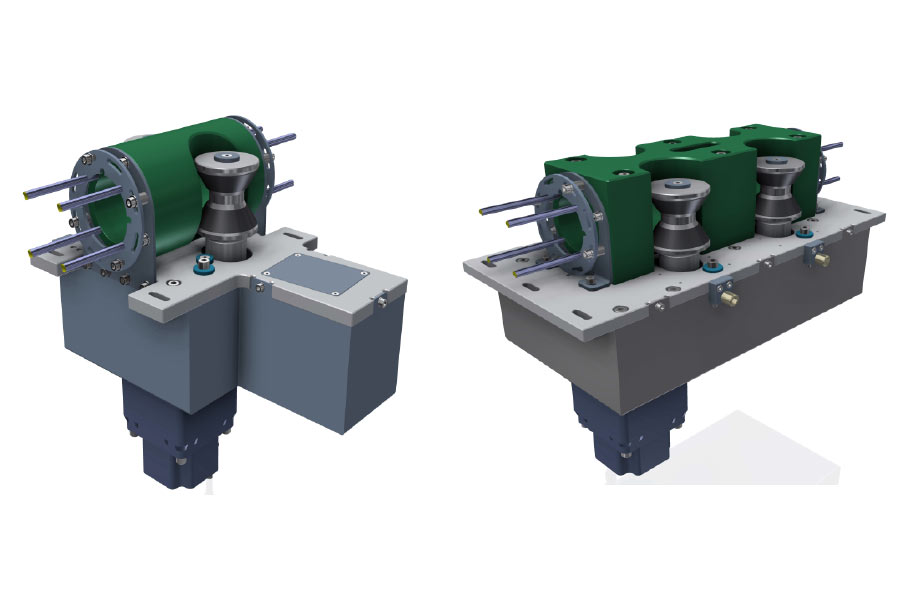

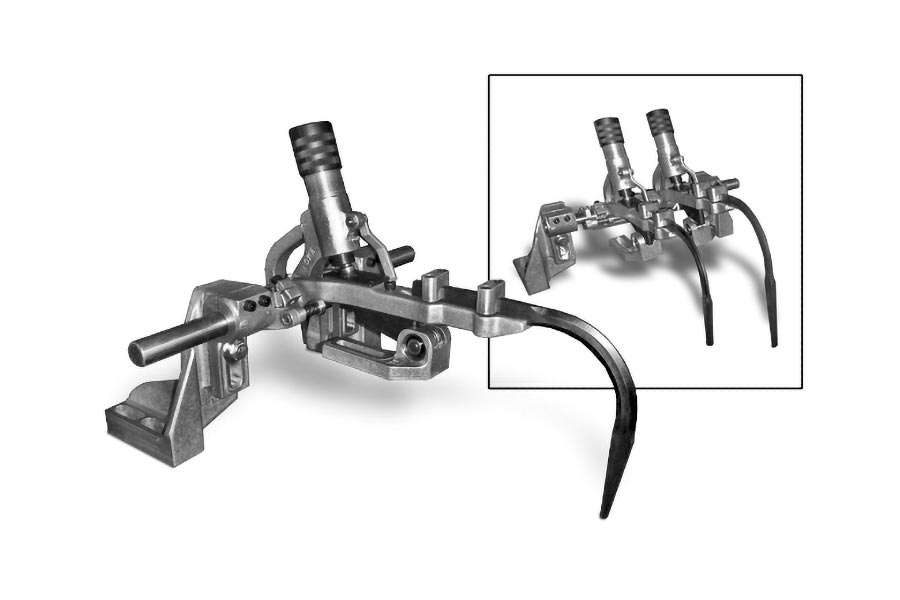

Pushers are a key ingredient in end handling. Our balancers for beverage end handling use 70 – 80 pushers in a typical installation! | Read more

Induction ovens are available in horizontal and vertical designs. These ovens save 70 – 80% of energy, compared to gas or electrically heated ovens. And no oven pockets and other maintenance on moving parts! | Read more

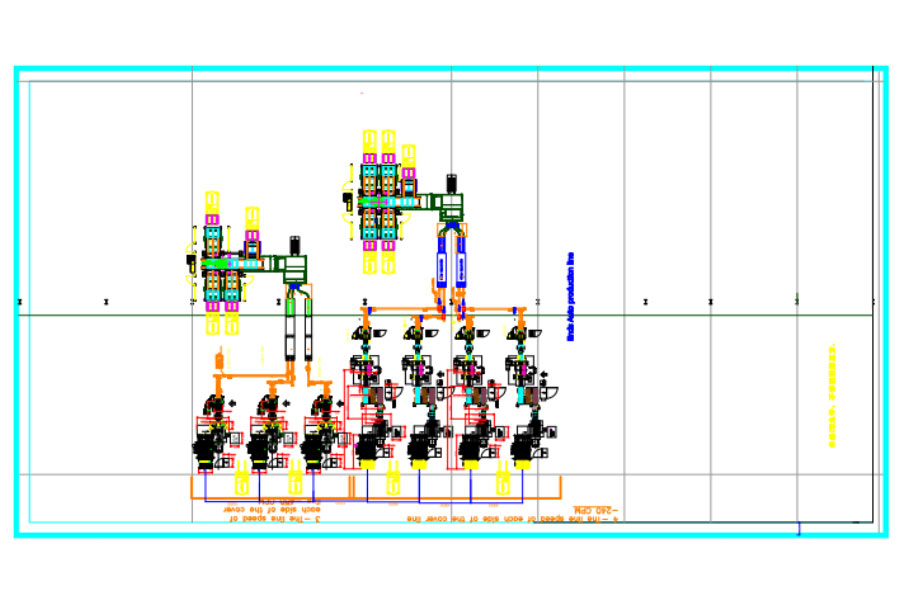

A first in end palletising: every end from one press is palletised on a distinct pallet. The four incoming lanes could of course come from a 4 lane conversion press – TRACEABILITY at its best! | Read more

We take over after the compound lining with conveyors, room for inspection stations for compound, curls, rivets, any desired parts of the ends at speeds up to 1500 epm, counting, bagging, palletising, strapping, wrapping. You just need to sell them and take them to the warehouse or the customer. | Read more

Ends coming from the production lines are accurately counted and pushed forward. A mechanical gripper transfers a stick of ends to wrapping station.Then the ends are wrapped automatically in film.A manual by pass bagging station for paper bags is included. | Read more

Wrappers and strapping equipment are examples of neccessary equipment for end of line packaging. These machines are not made by Container Machinery, but integrated into complete lines. | Read more

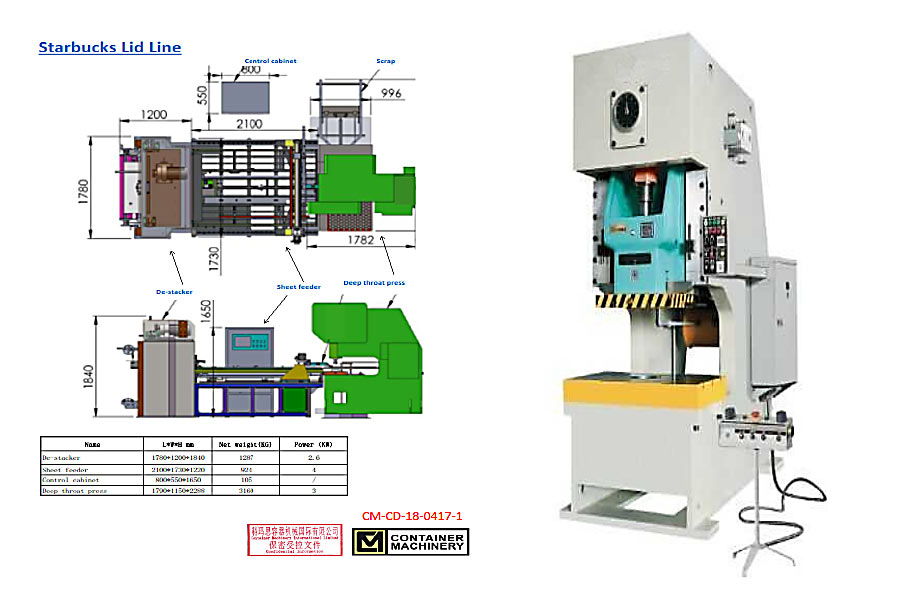

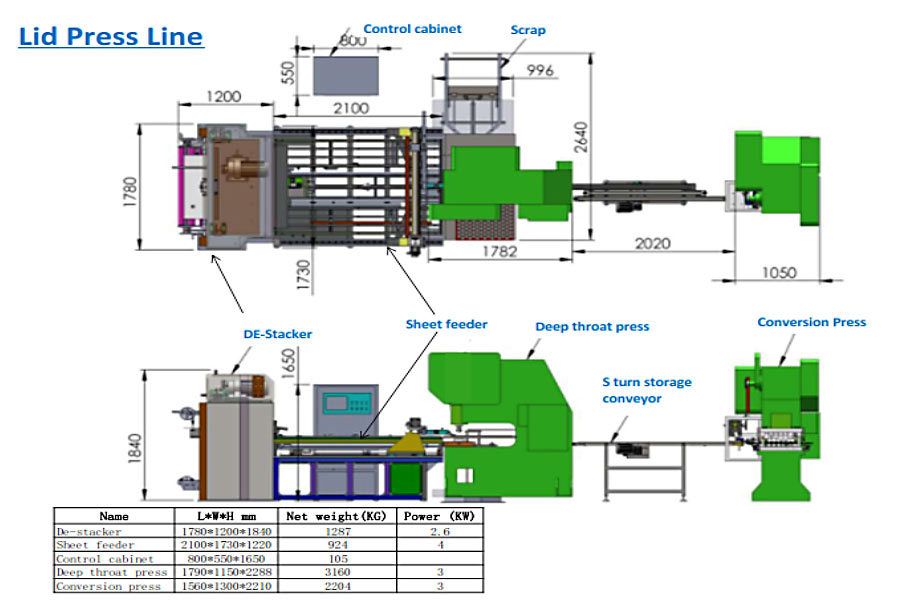

Simple C-frame presses with single or double sets of dies can make shells or drawn Slip Covers for fancy cans. The operations of blank / draw / outside curl can take place in one set of dies! No trim press or curlers needed. Save space, save money, save people. The | Read more

The example shows a line for shallow drawn containers or drawn lids for the fancy can making industry. | Read more

To maximise material use, sheet feeders have to be able to handle the sheets forward and side-ways, called a Zick-Zack motion. Our feeder does that with precision, resulting in a skeleton width of 0,8mm. The feeder can handle motions for single and multipleDies. Programs are stored for various jobs. | Read more

A simple tool to make the job of loading stacks of ends or blanks manually into boxes a lot more efficient and comfortable. | Read more

Container Machinery supplies various models of can end unwrapping systems, to remove paper bags, paper wraps or shrink film material. The system includes vacuum suction and balers for paper or plastic materials. | Read more

End Feeding System for beverage can filling, incl. de-palletiser un-wrapper, buffer, feeder. The filler of the filling line must never stop! Every step of the end feeding process is backed up by a manual action | Read more

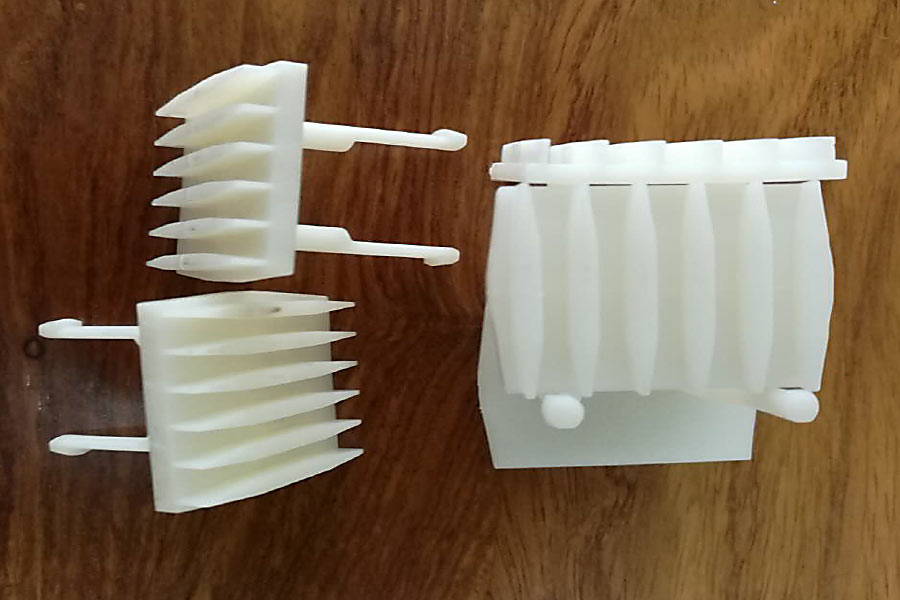

Replacement oven pockets for end drying oven. | Read more